Introduction to Automatic Powder Coating Line

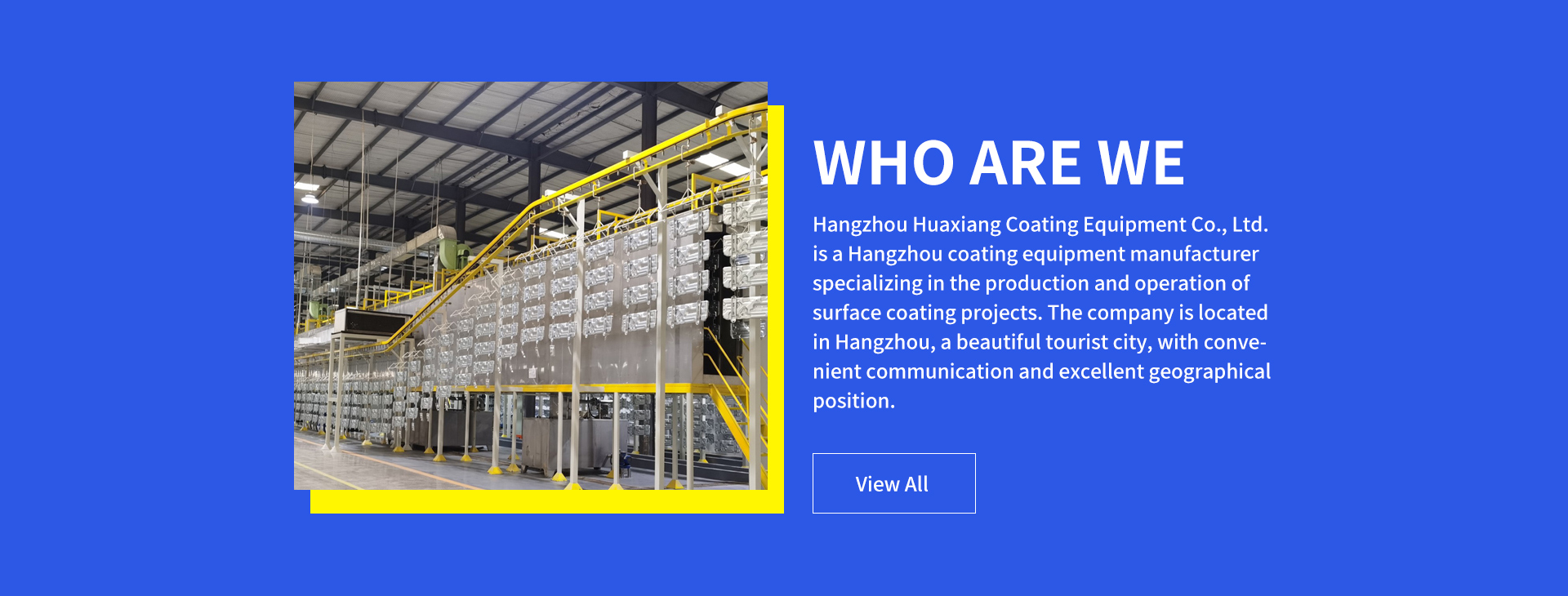

An Automatic Powder Coating Line represents a pinnacle of industrial innovation, meticulously engineered to streamline large - scale powder coating processes. This comprehensive system is composed of several integral components. The powder spraying booth serves as the initial stage, where an electrostatically charged powder is evenly dispersed onto the target objects. This booth is designed with precision to ensure uniform coating application, minimizing any potential for unevenness.

The conveyor system, a crucial link in the chain, functions as the transportation backbone. It smoothly propels the items through each phase of the powder coating journey, from the spraying booth to the curing oven. This continuous movement not only enhances efficiency but also guarantees consistent processing times for all items.

The curing oven, a high - temperature chamber, plays a pivotal role in the final transformation. Here, the powder - coated items are subjected to precisely controlled heat, which fuses the powder particles together, forming a durable and smooth finish.

Complemented by a sophisticated control unit, the entire operation is managed with remarkable precision. This control unit allows operators to fine - tune every aspect of the process, from the powder spray intensity to the curing temperature and conveyor speed.

Application Scenarios

In the automotive industry, the

Automatic Powder Coating Line is an indispensable asset. It is used to coat car bodies with a high - quality, corrosion - resistant finish, enhancing both the aesthetics and durability of vehicles. Additionally, it is extensively employed in coating various automotive parts, such as bumpers, wheels, and engine components.

Within the furniture manufacturing sector, metal furniture frames benefit greatly from the use of this technology. The automatic powder coating line provides a consistent and long - lasting finish, protecting the frames from rust and wear, while also offering a wide range of color and texture options.

The production of household appliances, like refrigerators and washing machines, also heavily relies on automatic powder coating lines. These lines ensure that the exteriors of these appliances not only look sleek but also withstand the rigors of daily use.

Price Range

The cost of an

Automatic Powder Coating Line can vary substantially based on its scale and features. A basic, small - scale setup, suitable for low - volume production, may start at approximately $50,000. This type of line typically comes with standard components and a relatively simple control system.

On the other end of the spectrum, a large - scale, high - tech line equipped with advanced features such as automated quality control, multi - color powder spraying capabilities, and high - speed conveyor systems can cost upwards of $500,000. These high - end lines are designed to meet the demands of large - scale manufacturing operations with high productivity requirements.

Correct Usage

Before commencing operations, operators must first program the control unit according to the specific coating requirements of the items. This includes setting the appropriate powder spray parameters, curing temperature, and conveyor speed.

Once programmed, items are carefully loaded onto the conveyor system. It is essential to ensure that the items are properly positioned to receive an even coating.

Subsequently, the powder spraying booth and curing oven are set to the correct parameters. During the operation, continuous monitoring is crucial. Operators should keep a close eye on the powder spray pattern, the temperature inside the curing oven, and the movement of the conveyor system to ensure that everything runs smoothly.

How to Choose

When selecting an

Automatic Powder Coating Line, production capacity is a primary consideration. Assessing the volume of items to be coated per day or per week helps in determining the appropriate line size and speed requirements.

The quality of components is also vital. High - quality powder spraying booths, conveyor systems, and curing ovens made from durable materials and with reliable manufacturing standards ensure long - term performance and reduced maintenance costs.

A user - friendly control unit is another key factor. An intuitive control panel with clear instructions and easy - to - adjust settings simplifies the operation and reduces the learning curve for new operators.

Safety Precautions

Maintaining a clear area around the line is essential to prevent tripping hazards. This includes keeping walkways free from obstacles and ensuring that any tools or materials are stored properly.

Proper ventilation in the powder spraying area is non - negotiable. Powder particles can be harmful if inhaled, so a well - designed ventilation system should be in place to extract the powder - laden air and replace it with fresh air.

Workers operating the line should always wear appropriate protective gear. This includes masks to filter out powder particles, gloves to protect their hands from the powder and any potential contact with hot surfaces, and safety glasses to shield their eyes.

Rationality Analysis

For large - scale production, an

Automatic Powder Coating Line offers a multitude of advantages. It significantly boosts efficiency by reducing the time required for manual coating processes. The consistent quality achieved through automated operations ensures that every item meets the highest standards.

Moreover, by minimizing the need for manual labor, it effectively reduces labor costs. The long - term cost - effectiveness is further enhanced by the reduced waste and higher production output, making it a wise investment for manufacturers aiming to optimize their production processes.

Q&A

A: The setup time typically ranges from 1 - 2 weeks. However, this can vary depending on the complexity of the line. A basic line with standard components may be set up relatively quickly, while a more advanced line with custom - built features may take closer to two weeks or even longer.

Q: Can I customize the conveyor speed?

A: Yes, most modern automatic powder coating lines are equipped with adjustable conveyor speeds. This flexibility allows operators to optimize the production process based on the type of items being coated and the curing requirements.

Q: What maintenance does the line need?

A: Regular maintenance is crucial for the smooth operation of the line. This includes regularly cleaning the powder spraying booth to prevent powder buildup, which can affect the spray pattern. Additionally, the conveyor and curing oven components should be inspected for any signs of wear and tear, and necessary repairs or replacements should be carried out promptly.

Q: Is it easy to train workers to operate the line?

A: With a user - friendly control unit, training new workers becomes relatively straightforward. Most modern control units are designed with intuitive interfaces, and comprehensive training manuals are usually provided. As a result, workers can be trained to operate the line in a relatively short time.

Q: Can the line handle different sizes of items?

A: Many automatic powder coating lines are designed with adjustable features to accommodate a variety of item sizes. This may include adjustable conveyor belts, powder spraying nozzles with variable reach, and curing ovens with flexible interior configurations.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com